Welcome to Kitaab Store (US)

Explore books from around the world. Use the search bar above or browse our selections below.

View All Items in USRecently Added (US)

Affordable Finds (US)

Nenjukku Nimmathi (Tamil Edition)

0.18 USD

Les Miserables

0.19 USD

Smriti's First

0.19 USD

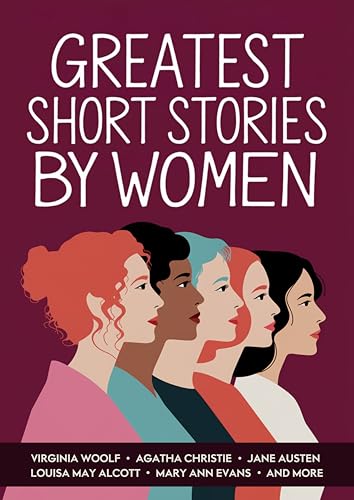

Greatest Short Stories by Women

0.19 USD